More than 48,000 attendees and over 1,700 exhibiting companies made up the huge event which presented the chance to see – and even try out – the latest industry products and developments at McCormick Place.

Attendees could find tools to improve productivity, increase profits and discover new solutions for metal forming, fabricating, welding and finishing needs.

There were also educational sessions and expert-led presentations covering the latest trends and technology in the metal forming, fabricating, gases and gas equipment, welding and finishing industries.

Some of the presentations focused on the skills shortage and ways of addressing the problem. There was also a lot of talk about the benefits of adding automation, Artificial Intelligence (AI) and machine learning to your business, which are ways of overcoming the problem of a skills shortage.

And rather than taking jobs away from people, it was argued that automation will make new jobs.

Tyler Vizek, Project Engineer, MxD, said at one lunchtime presentation at the FABTECH Theater, “Whether it’s robotics or digital automation, there this thought that the robots are here to take jobs. We have to look at it that it’s not the job that it takes away but the tasks that make up that job. Whether it’s repetitive or dangerous, this is where automation will make the biggest difference. Automation is going to allow us to free up time for workers to do jobs that are uniquely human, such as leading, creating, strategizing, and emphasising. It’s about redefining humans’ role in the manufacturing environment. AI or robotics is a labour multiplier. It’s not about what jobs robots are going to replace. Instead of replacing jobs, it’s moving people to jobs that they are good at.”

There were three huge halls full of activity, and here are some of the companies that caught the eye:

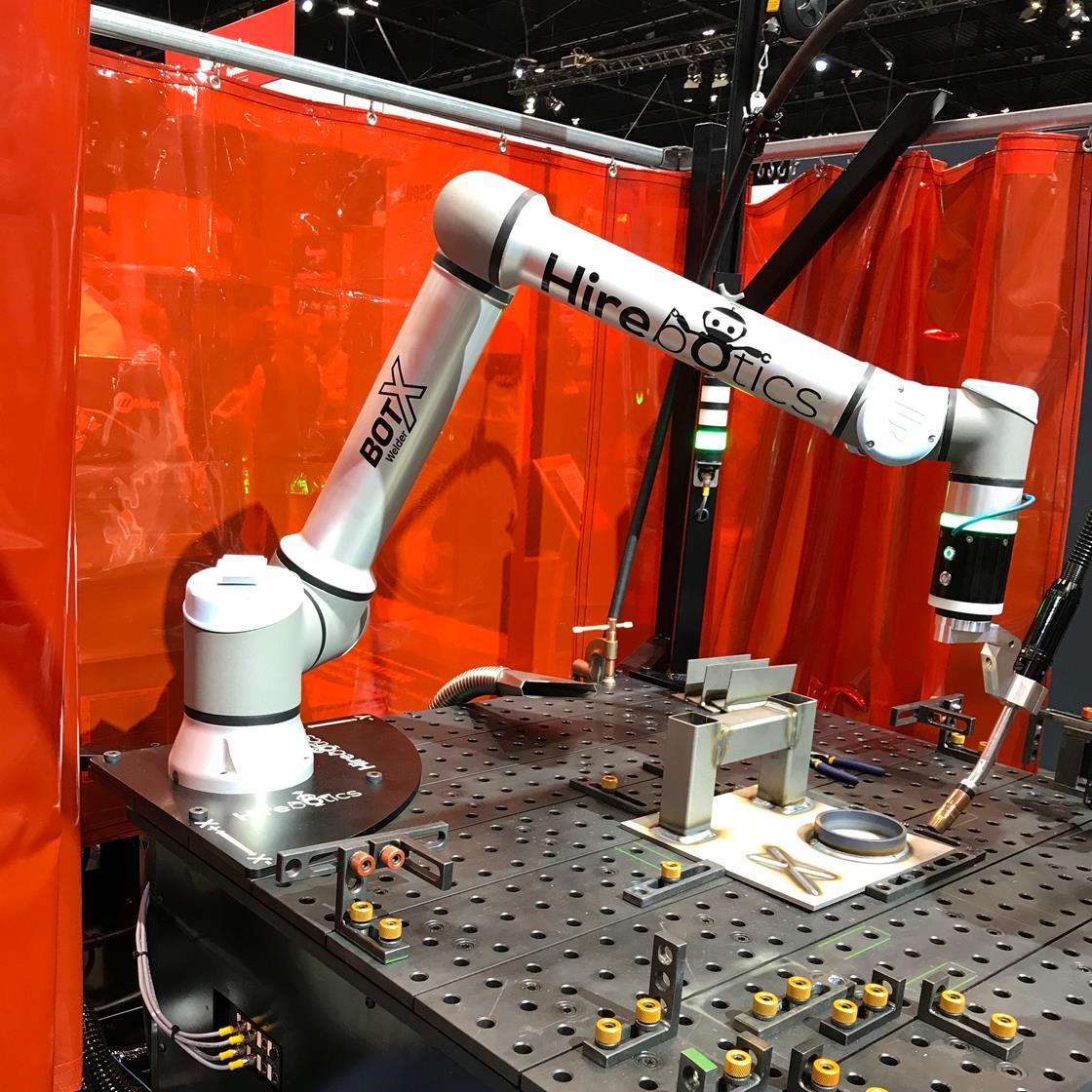

Universal Robots powers three cobot powered path-processing solutions that were exhibited at FABTECH: BotX Welder by Hirebotics, Red-D-Arc and Airgas; Vectis Automation’s Cobot Welding Tool; and SnapCut by ARC Specialties.

Cobots and automation are everywhere at FABTECH each year now, as automation increasingly plays a bigger role in the industry.

With the average age of welder in the US now 55 years old, and fewer than 20% are under the age of 35, according to the American Welding Society, cobots are being employed as a resolution to the labour shortage.

“Addressing the severe labour shortage in weld shops with cobots is now a solution that we see rapidly emerge as industry leaders and innovators start offering automated welding tools utilizing the Universal Robots’ platform,” said regional sales director of Universal Robots’ Americas division, Stu Shepherd.

Powered by Universal Robots’ UR10e collaborative robot, the Vectis Cobot Welding Tool is a portable, safe, versatile, and extremely easy-to-use solution that is even available as a low-risk, no-capital rent-to-own option. The Vectis Cobot Welder is commonly 25-40% less expensive than the all-in cost of a small traditional robot welder.

At the Airgas exhibit, there was a close-up look at the new, collaborative robot welding system from Red-D-Arc, Air Liquide and Hirebotics. The BotX Welder system can help automate process and increase the size of workforce on-demand without any capital investment; add an operational cobot to your workforce with just a few hours of training; control expenses by paying for the BotX by the productive hour when you need it, and keep production running with access to a continuously updated library of welding procedures and 24/7 virtual support.

There are no installation costs with BotX, and with cloud monitoring, manufacturers pay

only for the hours the system actually welds, thereby enabling the manufacturer to hire and fire BotX as business needs dictate. Customers can teach BotX the required welds simply via an intuitive app on any smartphone or tablet utilizing a library of welding recipes contained in the BotX software developed specifically for the BotX and optimized to work with Airgas’ ARCAL shielding gas.

Xiris Automation Inc. and its weld cameras got a lot of attention. Norm Sted, Director of Sales and Business Development, said, “We brought out four new products at FABTECH. We’re trying to move the needle when it comes to technology, and the industry is driving it.”

Chart was showcasing its new Trifecta® Pro 30K Gas Supply System, a solution for reliable and continuous laser assist gases for delivery pressures up to 600 psig MAWP with 550 psig MAOP and flow rates up to 30,000 scfh. It is scheduled for release in the first quarter of 2020.

Drawing liquid from a standard bulk tank, the Trifecta system boosts the liquid pressure by alternatively feeding two liquid cylinders equipped with innovative multi-function pressure building vaporizers. The Trifecta solution has no down-time and minimal losses when compared with other laser assist gas solutions.

Chart was also promoting its year end sale, with 5% off all stock model Dura-Cyl liquid cylinders.

ESAB had a great exhibition of its latest products, among which are the new Victor® D1G Dome Load regulator, which is built to handle exceptionally high gas flow rates, provides stable delivery at flow rates exceeding 30,000 cubic feet per hour, and is designed for tube trailers, cylinder bundles and gas bundles.

“High flow applications, such as a 10kW laser, require more nitrogen, so we increased the diameter of the inlet and outlet ports by 50 percent compared to our previous design,” said John Henderson, Sr. Director – Industrial & Specialty Gas Products, ESAB.

“We moved from a 100-micron filter to a 50-micron filter to better prevent contamination and keep internal components cleaner. The filter is easily replaceable by simply removing the retaining ring holding it in place. Other high-flow regulators use a separate dome regulator and a pilot regulator, but the D1G incorporates them into one piece, which is why we refer to the D1G as a pilot dome load regulator. The Victor design makes it easier to remotely control On/Off because there’s only one component to control.”

ESAB University held hands-on demonstrations with tips from experts at stations for welding, manual plasma cutting and oxy-fuel cutting, the later highlighted by the Victor® Rulers of the Flame cutting contest.

ESAB has combined with the leading online educational site Weld.com to offer more courses at ESAB University and added technical presentations from ESAB experts.

Lincoln Electric’s expansive exhibition showcased its latest releases, including the POWER MIG® 140 MP® multi-process welder, a lightweight and portable welder that connects to 120 volt power. Also on display was the brand new the Ranger 330MPX, a gas engine driven welder and generator that gives you more power and versatility in a smaller, quieter package.

Thermo Scientific was demonstrating the Niton Apollo handheld LIBS analyzer, the new Thermo Scientific Niton Apollo handheld LIBS analyzer, a brand new portable “point and shoot” instrument that can positively identify even low levels of carbon, as well as other devices used by customers in the metal processing, manufacturing and metal fabrication industries.

The Niton Apollo features an effective laser and high purity argon purge to generate lab quality results. Specifically engineered to provide superior analysis and low detection limits, users can view alloy identification and advanced averaging in about 10 seconds. It works without a hefty argon tank, but instead uses an argon cannister.

There were a lot of companies promoting the benefits of onsite nitrogen generation, and noted that they are experiencing an increased demand in their products.