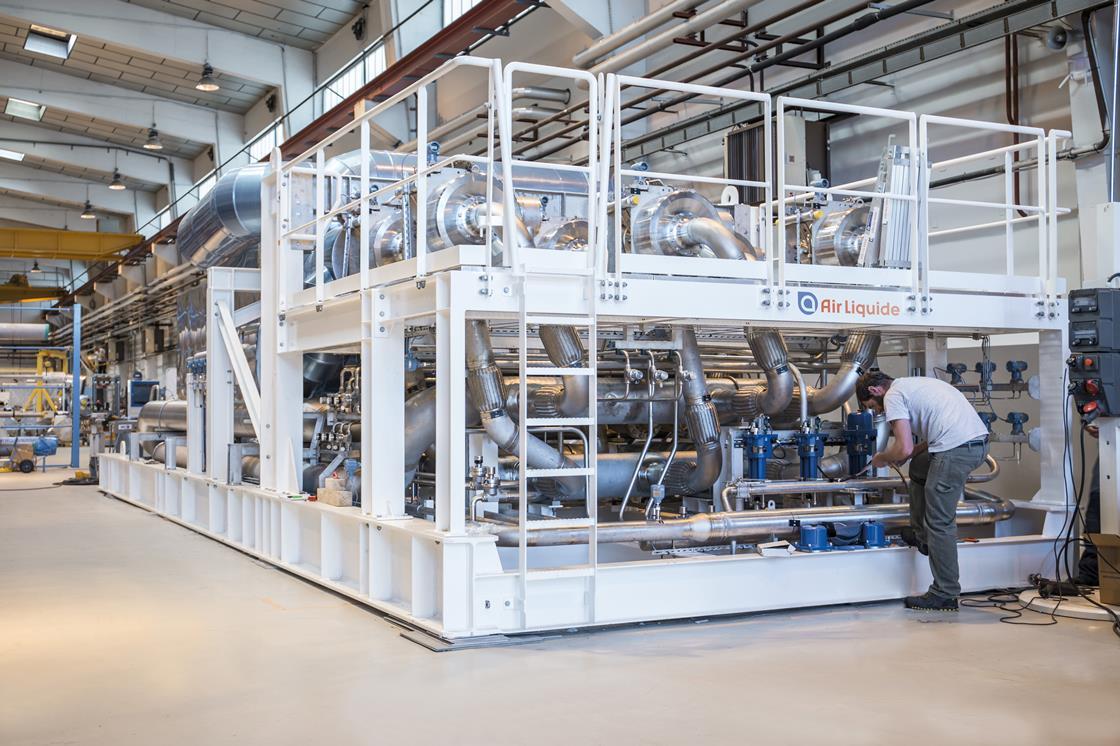

Based on the Turbo-Brayton physical principle, the French firm’s exclusive, patented cryogenic equipment reliquefies natural gas boil-off in LNG vessels in order to significantly reduce greenhouse emissions during transport.

In the maritime industry, LNG carriers transport LNG from methane-producing countries to consumer countries over very long distances.

This natural gas, which is cold in its liquid state, tends to reheat and in part evaporates during transport.

Air Liquide has developed a refrigeration and liquefaction technology based on the Turbo-Brayton physical principle, which reliquefies the evaporated natural gas and keeps it in the container in liquid form.

Source: Air Liquide

“Quick and easy to install, this patented system is a reliable and economical solution suited to all types of storage, on new and existing vessels,” Air Liquide explained in a press release.

“Oil-free, it requires zero maintenance for five years and boasts proven efficiency.”

Air Liquide said it had sold more than 30 pieces of this cryogenic equipment, intended for LNG carriers and bunker vessels, in 2019.

The company said this commercial success is helping to meet the challenge of climate change, as part of Air Liquide’s climate objectives.

Read more like this – subscribe today

Enjoyed this story? Subscribe to gasworld today and take advantage of even more great insights and exclusives in industrial gases.

Visit www.gasworld.com/subscribe to access all content and choose the right subscription for you.